Design:

The front-wheel deflectors were designed to improve vehicle handling at high rates of speed. By reducing the airflow which makes it into the wheel wells and directly hits the front wheels, we are able to reduce drag. By persuading the airflow to go to the underbody, we are able to increase the downforce of the vehicle as well. We then took this a step further, and created a design purpose-built for the splitter we produce, as well as an OEM front bumper, each of which ships with the front wheel deflector kit.-

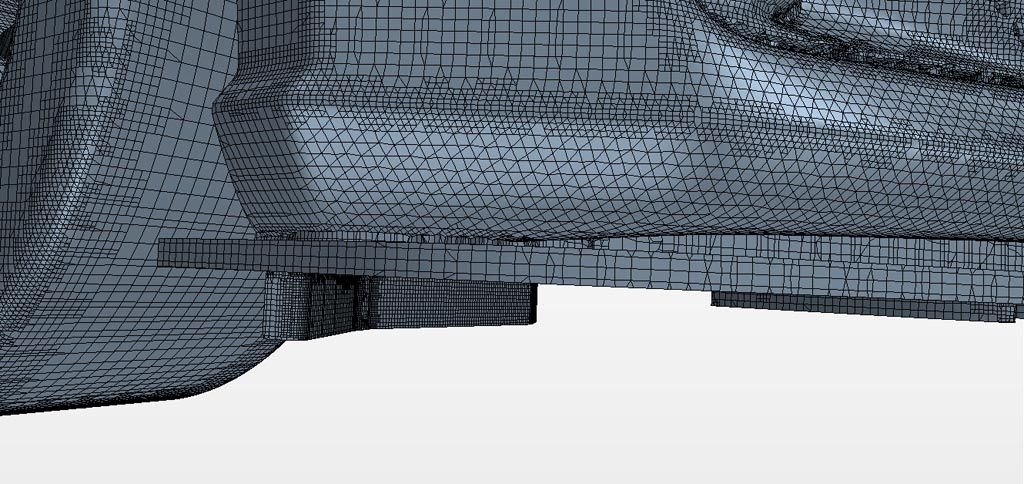

Like all of our analysis before, each analysis was done using a half-car analysis since no yaw testing was completed. This is done using symmetry down the centerline of the car. Significantly less computational processing power is necessary when using a half-car model and was the reason behind this analysis approach. The meshing of the car is done using first a surface mesh and then volume mesh. To find a suitable mesh size for the analysis, a grid convergence study was done. A volume mesh count of 10 million cells was considered within the room for accuracy using mesh sensitivity analysis.

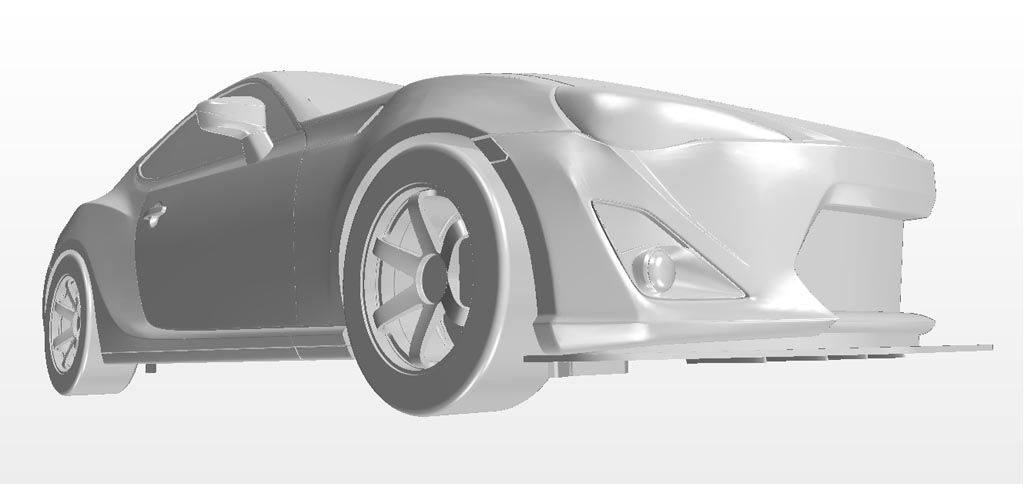

FT86 Geometry that was Tested in CFD

Close Up of Surface Mesh

The CFD post-processing offers both visualizations of the flow and numerical data. Using both of these we can make educated guesses as to the changes it makes to the vehicle's overall performance.

Pressure plot on the front-wheel deflector

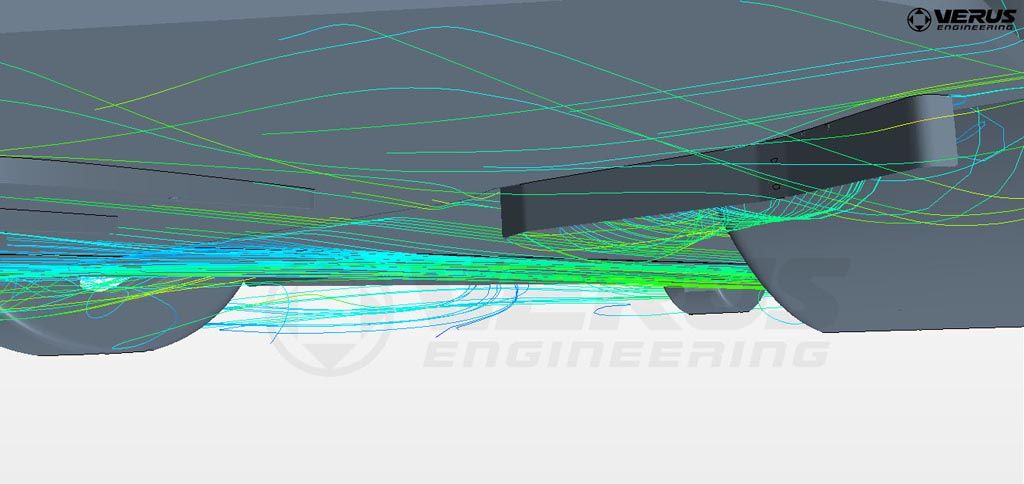

Streamlines are another powerful tool to find where the air appears to be moving and if any vortices exist where we intend them to be.

Streamlines on the front deflector

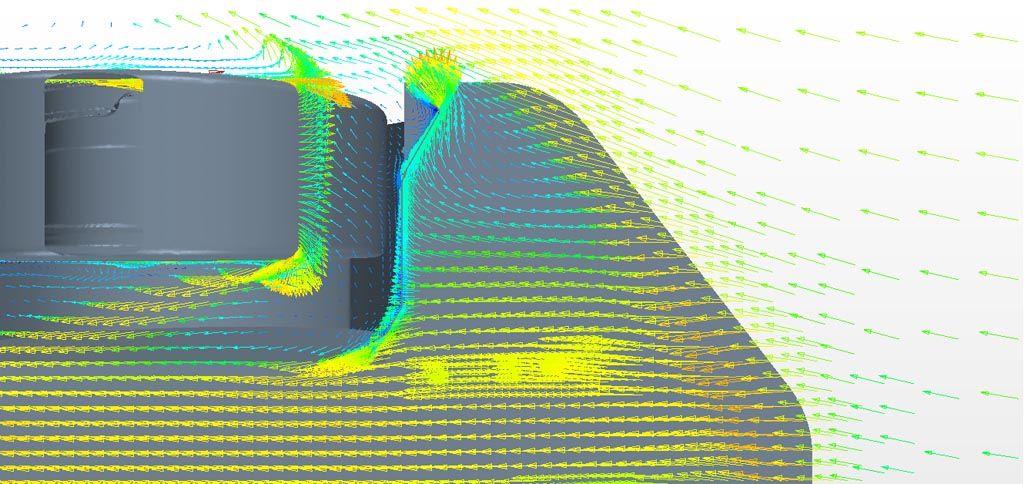

Finally, we use vector arrows to visualize where the air is flowing and at what magnitude as well a video to view flow.

Vectors as air velocity on the car’s underbelly

Numerical Data:

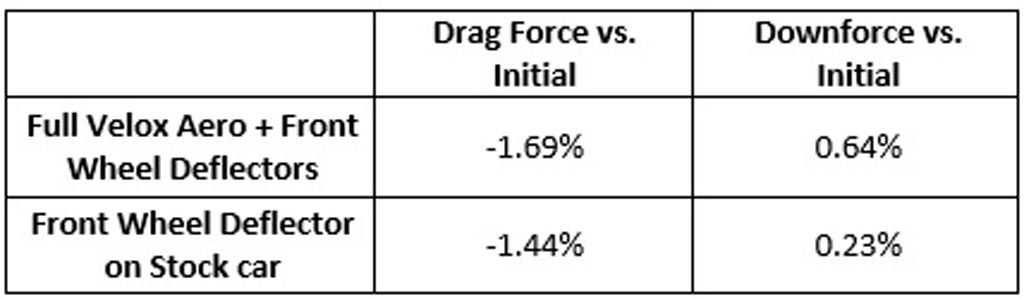

The front-wheel deflectors reduced the drag of the vehicle slightly with very little numerical change in downforce. While we believe our CFD analysis to be accurate, these analyses do have a hard time picking up small changes like these on the underbody of a somewhat accurate model.

These changes are not terrible considering the size and location of these components though.

Conclusion:

The big thing to remember with a component like this is that the theory and science, as well as nearly every OE manufacturer, backs its function. Just because the CFD analysis does not show a large numerical change does not mean that real-world results will not show more benefit. We do believe real-world downforce will be more than what CFD showed but this is an educated guess. At 70 MPH, our test vehicle saw a consistent increase of 0.3 MPG from the addition of this component.

Real-world benefits may differ as this is computational analysis. Something as simple as ride height or wheel choice can vary results, as well as various other aspects. Real-world results could be better or worse than what is shown above.

Very few companies perform CFD or wind tunnel analysis on any of their aerodynamic pieces. As a consumer, you can rest assured that you are receiving a quality component with engineering analysis and theory backed components that perform as well as they look.

FRS/BRZ Front Wheel Deflectors – CFD Analysis